Heat transfer devices represent an important part of our routine, frequently hidden in plain sight, yet they play vital roles in many applications from the comfort of our homes to massive industrial processes. Whether you're enjoying a pleasant shower, driving your car, or sipping coffee, it's likely a heat exchanger operates behind the scenes to improve your comfort and more effective. Understanding how these devices work and where they are used can reveal to the importance of heat transfer technology in our current era.

In this article, we'll examine the diverse applications of heat exchangers that you may not be aware of, as well as discuss the multiple types, their efficiency, and care. From HVAC systems that ensure our indoor environments comfortable to innovative materials that define the future of heat exchangers, we will reveal the many facets of this essential technology. Embark on this journey on this journey to uncover how heat exchangers are not just a engineering need but also a significant component in enhancing sustainability and energy efficiency across multiple industries.

Grasping Heat Exchangers

Heat exchangers are vital devices used to conduct heat between various fluids without mixing them. They operate on the concept of heat transfer, which can take place through conduction, fluid movement, and in some cases thermal radiation. By allowing the optimal movement of thermal energy, these devices play an important role in various applications, from manufacturing to everyday appliances.

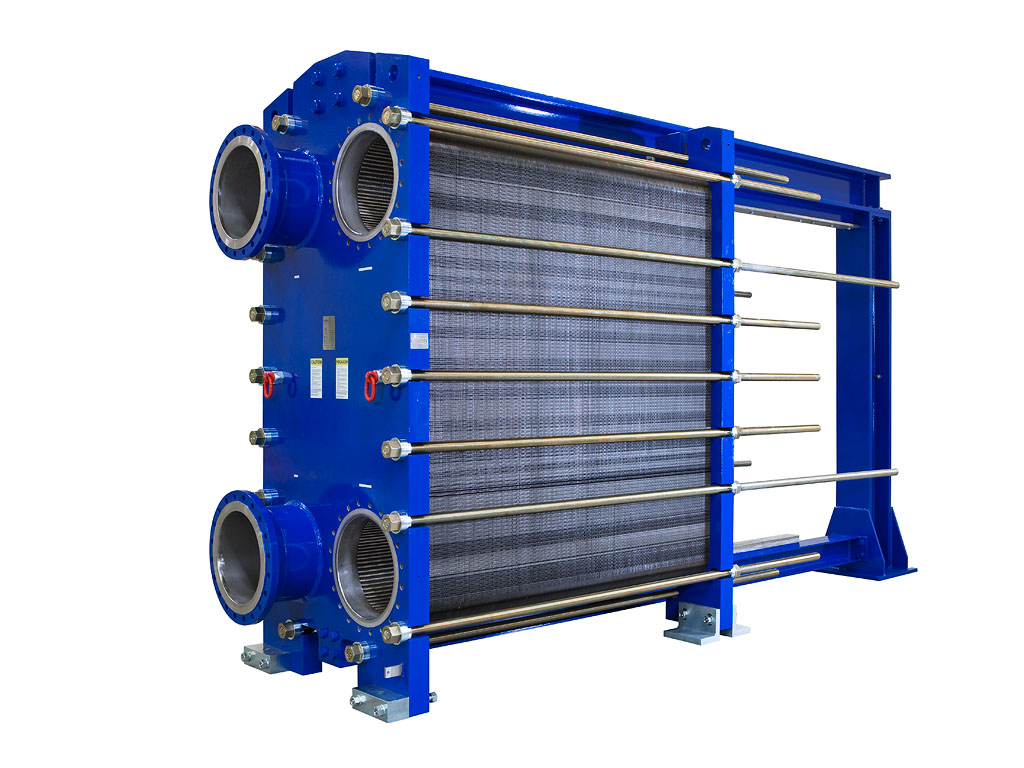

These devices come in different formats, each adapted for specific functions. Common designs include tube and shell, plate, and air-cooled type heat exchangers. Each type has its own strengths and best use applications, depending on considerations such as size limitations, thermal needs, and the nature of the gases involved. Comprehending these differences is key for choosing the right heat exchanger for any given context.

In common life, heat exchangers are more prevalent than many people realize. They are present in systems like HVAC units in homes, automotive radiators, and even in the food and beverage industry where they help maintain safe processing temperatures. By effectively managing heat transfer, these units contribute substantially to energy efficiency and total system performance, making them essential in both residential and commercial contexts.

Uses in Different Fields

Heat exchange systems are essential parts in various fields, carrying out the key function of shifting heat between two liquids. In secondary chiller loops & drink sector, for example, heat exchangers are deployed to pasteurize liquids and preserve quality during processing. They help to effectively manage temperature, securing that products like milk and juice are heated rapidly to destroy pathogens while maintaining flavor and nutrients. This implementation not only enhances food safety but also improves processing efficiency.

In the chemical processing industry, heat exchangers enable reactions and processes that require precise temperature management. They are often employed in reactors and distillation columns, where regulating temperature is vital for optimizing yields and reducing energy consumption. By effectively transferring heat away from exothermic reactions or supplying heating for heat-absorbing processes, heat exchangers play a key role in maintaining best operating conditions and improving overall process efficiency.

The energy sector also relies heavily on heat exchangers, particularly in power plants and renewable energy sources. In classic power plants, these devices help reclaim waste heat from the emissions gases of turbines, allowing for better efficiency and reduced emissions. In renewable applications, such as earth heat and solar thermal systems, heat exchangers change natural heat sources into usable energy. Their role in these sectors underscores the versatility and significance of heat exchangers in boosting energy efficiency and supporting sustainable practices.

Upkeep and Efficiency

Appropriate maintenance of heat exchangers is crucial for guaranteeing their efficiency and prolonging their lifespan. Regular inspections and cleaning are required to prevent fouling, which can greatly hinder heat transfer efficiency. Accumulation of deposits can create barriers around the heat transfer surfaces, leading to increased energy consumption and operational costs. Establishing a scheduled maintenance plan can lessen these issues, resulting in enhanced performance and reduced downtime.

To optimize energy efficiency, it is critical to track the operating conditions of heat exchangers constantly. Digital monitoring technologies can provide real-time data on temperature, pressure, and flow rates, enabling for prompt adjustments as needed. By analyzing this data, operators can identify potential problems early, optimize performance, and reduce the risk of unexpected failures. Efficient heat exchangers contribute to overall system efficiency, resulting in lower energy bills and a reduced carbon footprint.

Ultimately, selecting the right materials and designs for heat exchangers can further enhance maintenance and efficiency. Using corrosion-resistant materials like stainless steel not only increases durability but also reduces the frequency of replacements and repairs. Innovations in compact designs, such as gasketed plate heat exchangers, allow for more convenient access during maintenance. By prioritizing these factors, industries can ensure that their heat exchangers operate at peak efficiency while reducing long-term costs associated with maintenance and replacements.